Findings Management

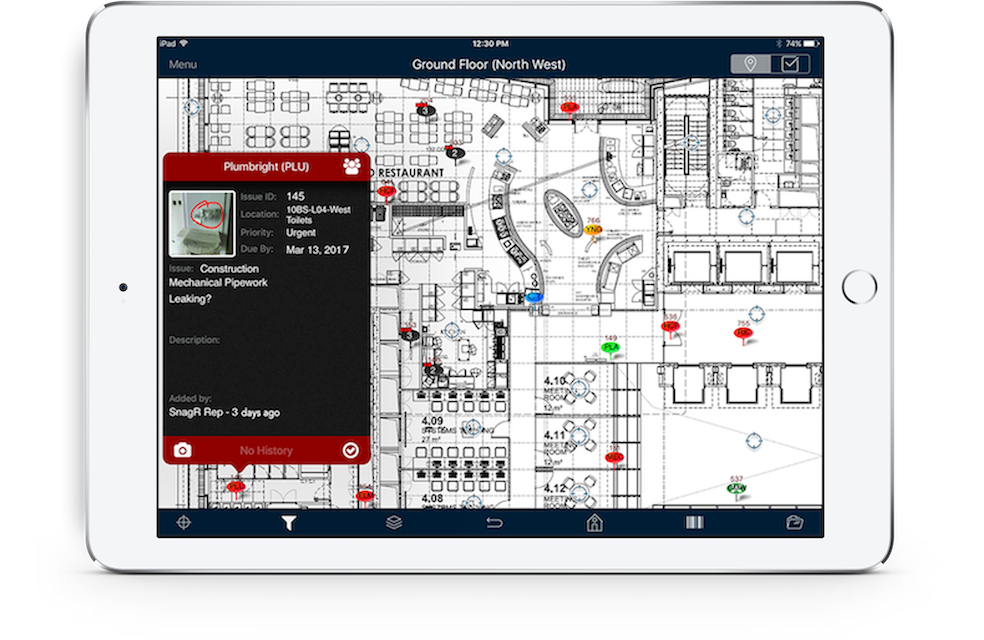

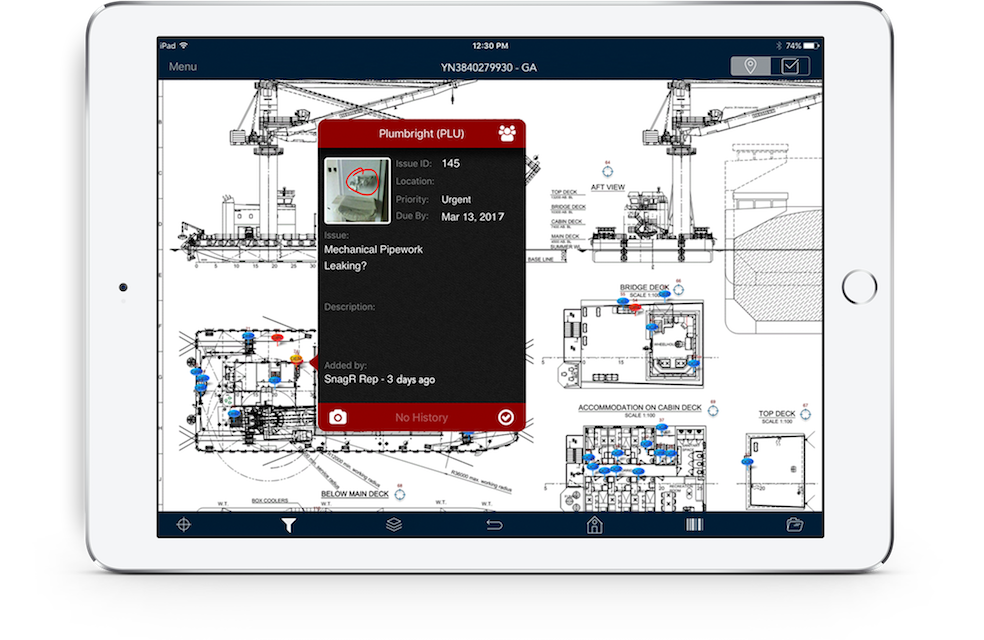

Work Offline

Work offline to link issues, defects and other findings to the drawings to capture directly where and when you find them, and make it easy to locate for the maintenance team.

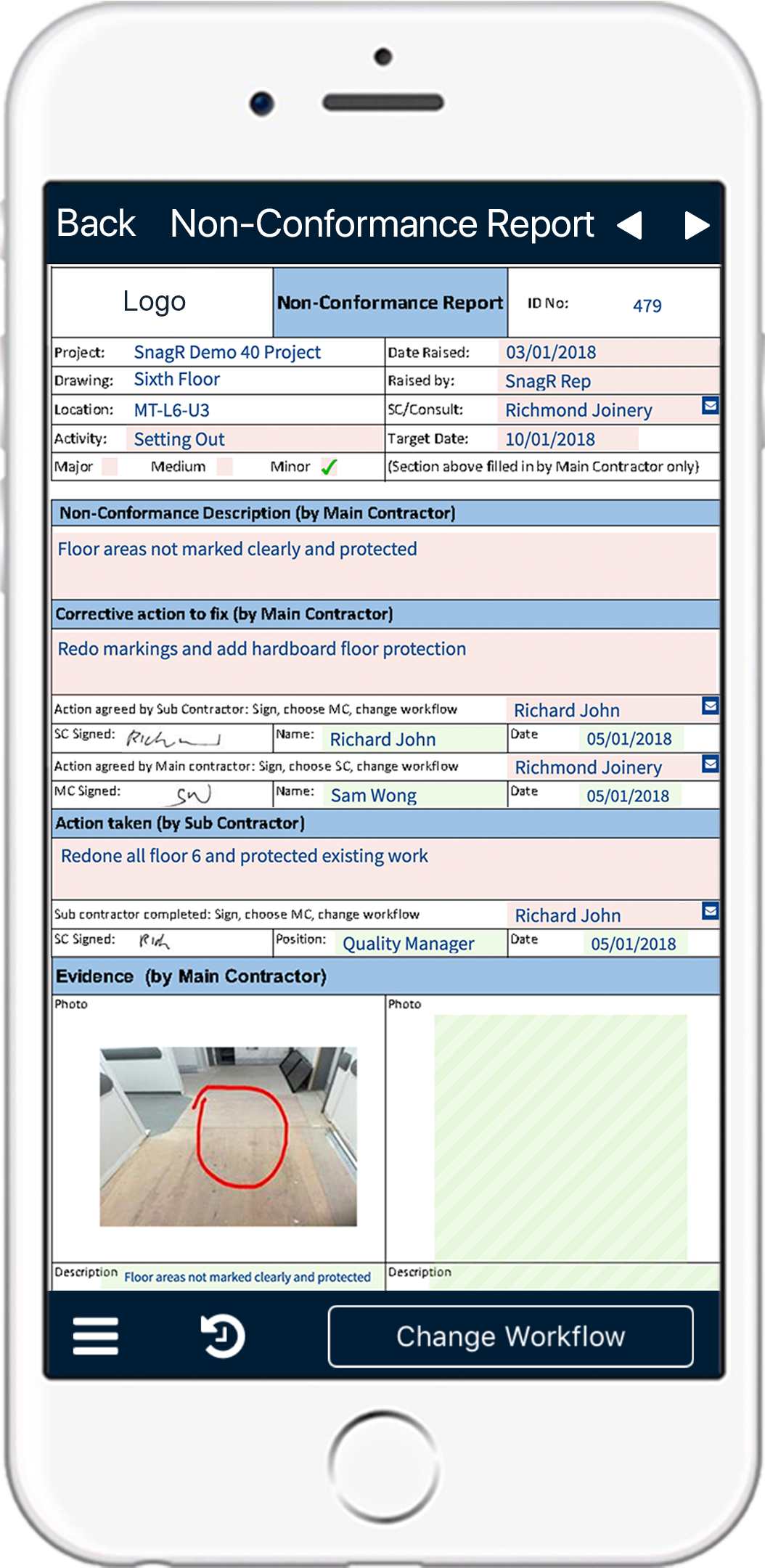

Customised Workflow

Design or import your company forms and workflows

Good Manufacturing Practise (GMP)

Capture Findings

Capture a richer set of information with marked up photos, severity and your own standardised GMP findings list.

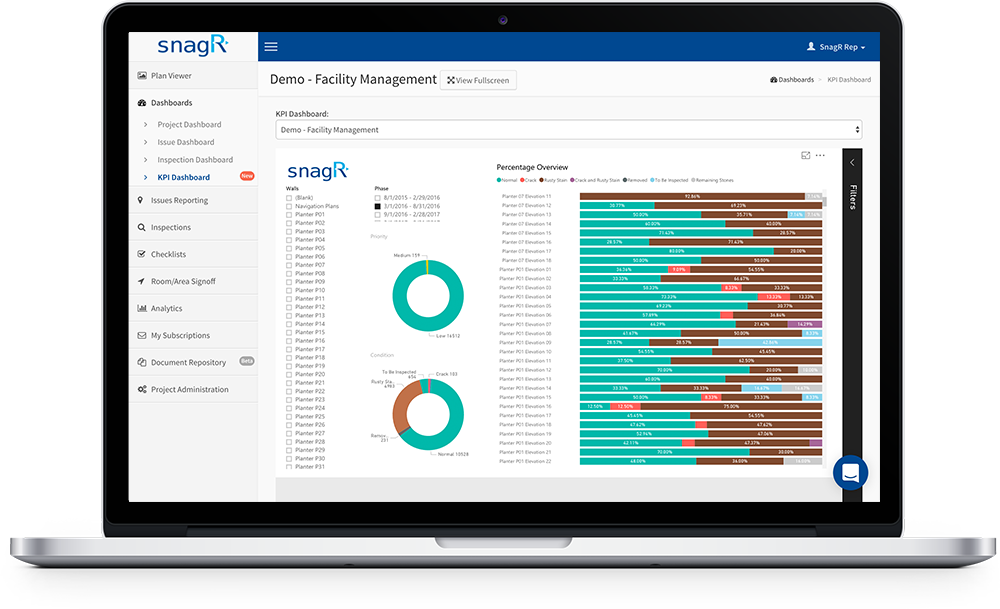

Automated Reporting & Analysis

Reporting & analysis is updated in near real-time with results automatically calculated saving huge amounts of error prone manual reporting.

Standardisation

Standardise your GMP process across all of your facilities, allowing you to concentrate on continual improvement rather than tabulating data.

All-in-one Dashboard

Analyse the performance of all your facilities from a single report or dashboard and interrogate your data for insights

Customer Story

manufacturing-solutions-three

Digitise Forms

Standardise and digitise your BO forms to directly record observation items via the mobile app, allowing a richer set of data with photos, signatures and constrained lists.

Eliminate Admin Workload

Removing error-prone data-entry via Excel or other manual methods for speed.

Real-time Analysis

Use real-time analysis to monitor trends, performance and issues across all of your facilities over time.

Try it Yourself

Total Productive Maintenance (TPM)

Proof of Location

Photographs, signatures and other data is captured using the mobile app with QR codes providing proof of position.

Photographic Evidence

Easy to verify that autonomous maintenance is being taken place with photographic evidence offering proof

Quick Fix

Issues can easily be flagged for the Maintenance / Engineering team to follow up.

Trend Analysis

Automated dashboards and reporting enables analysis of common trends and issues